Optimizations and applications of wide-band gap (wbg) semiconductor devices for ev systems

10/29/2022 10:42:58 AM

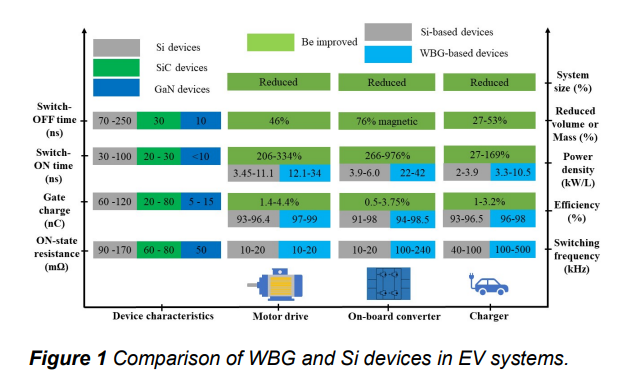

The electrical vehicle (EV) industry is now able to manage EV energy requirements by introducing power electronics systems that determine the energy, cost, and mileage of the devices. Despite other systems and components in an EV, power semiconductor devices increase the efficiency as well as the power density of the system. Using Wide-bandgap (WBG) materials at the system level converters reduces the system size and volume, increasing the overall performance and power of EV systems. They are considered next-generation power semiconductors because of their ability to switch at high speed when supplied with high voltages.

Silicon Carbide (SiC) and Gallium Nitride (GaN) are the WBG semiconductors that are widely used these days. Although there is a lot more scope for the development of WBG semiconductors, they are recognized as more efficient and reliable devices. These devices are more effective as they are able to overcome the challenges of EMI noise levels and provide suitable gate driver design and PCB layout.

The dominance of WBG semiconductor devices over Si

Of the three materials (GaN, SiC & Si), gallium nitride has the highest electron mobility, making it the best choice for applications with extremely high-frequency requirements. Contrary to silicon and GaN, silicon carbide has a higher heat conductivity. As a result, SiC is more effective in high-temperature applications. GaN continues to be the top material for radio-frequency fields, where the voltages do not reach extremely high values but the breakdown electric fields are stronger. Using WBG materials lowers the expenses as the heat dissipation is reduced thus leading to a reduction in power loss and making them more efficient than silicon equivalents.

The bandgap of Silicon (Si), Silicon carbide (SiC), and Gallium nitride (GaN) are 1.12 eV, 3.2 eV, and 3.43 eV respectively. The thermal energy of the electrons in the valence band grows as the working temperature rises, and once a certain threshold temperature is achieved, the electrons cross over into the conduction band. WBG semiconductors may achieve substantially higher temperatures without the need for electrons to build up energy due to their large energy gaps. As a result, the operating temperature of a sustained semiconductor increases with increasing bandgap.

Applications of GaN & SiC devices

SiC is used in Schottky diodes and Merged pin Schottky (MPS) diodes for EV onboard converters with a power rating of about 1.2kV/50A. Power electronics converters generally make use of enhancement power mode transistors to reduce the device gate driver fault These transistors are the normally-on SiC JFET along with low voltage Si MOSFET in cascade structures. SiC power modules can reach high current values of about 800A making it widely applicable for the requirement of peak currents in EV motor drives.

GaN transistors are available in three categories: cascade transistors, electron-mobility transistors (HEMT), and gate-injection-transistor (GIT). For making power modules more convenient, enhancement mode GaN-HEMT is fabricated as normally-on devices which have the natural existence of electrons in their channel. GaN-HEMT and cascade transistors operate in the same manner as MOSFETs as both of them are devices controlled by voltage and they own a bidirectional flow of drain-source current. GIT is a normally-off GaN transistor which is a current-controlled device. GaN devices with integrated gate drive devices are now available with SMD-type packaging that reduces the value of Lara of interconnection.

WBG Semiconductors Devices for EV Systems:

WBG semiconductors like SiC and GaN are used instead of Si power semiconductor devices in Electric Vehicle systems as they provide better applications. Apart from the advancements in EV systems, the industry is facing issues related to device power losses and EMI noise levels because of the fast switching transition of SiC devices.

Different operating conditions are implemented to characterize SiC MOSFET

● Nonlinear inter-electrode capacitance

● Hard switching and soft switching conditions

● Device inter-electrode capacitance losses

● Multiple current probe methods

Fig 2: Characterizing device of SiC MOSFET Fig 3: Multiple current-probe methods and

under various operating conditions. Two-port characterization method.

The multiple current probe method is implemented to measure power transistors' inter-electrode capacitance. In this method, the Vector network analyzer(VNA) introduces AC small signal current in the measuring circuits through the current injection probe (CIP), which is measured by the Current receiving probe (CRP). External DC voltage source and impedance analyzer(IA) are also used to measure the device's inter-electrode capacitance, which helps determine power transistor switching loss and time. Power losses in devices can be reduced by using the soft switching method.

The device reliability of GaN power transistors is an important factor for their widespread application in EV-based power electronic systems. We can reduce the EMI noise level by decreasing the parasitic capacitance of the GaN-based power converter which is achieved by reducing the area between the ground plane and the switching node.

Conclusion

As a result of the Wide-Bandgap semiconductor's exceptional physical and electrical properties, the materials are ideally suited for meeting the optimal performance requirements of a wide range of circuit designs and architectures. These requirements are high-frequency power applications, including power and operating-temperature extremes. GaN and SiC technologies are poised for dominance in power electronics applications, where their properties suit requirements for compactness, lightweight, high efficiency, and high-density power, as silicon approaches its application limits both in power and frequency. The cost-cutting and overall heat dissipation problems which in the case of semiconductors are caused by conduction and switching losses remain major technological obstacles. Some faults in the carbide component of SiC must be fixed, and more serious problems in the gallium nitride production procedures must be solved.

References:

[1] T. V Do, K. Li, J. P. Trovão, and L. Boulon, "Reviewing of Using Wide-bandgap Power Semiconductor Devices in Electric Vehicle Systems : from Component to System," 2020 IEEE Veh. Power Propuls. Conf. (VPPC), Gijon, Spain, pp. 1–6, 2020, doi: 10.1109/VPPC49601.2020.9330854.

[2] K. Li, P. Evans, and M. Johnson, "SiC/GaN power semiconductor devices: A theoretical comparison and experimental evaluation under different switching conditions," IET Electr. Syst. Transp., vol. 8, no. 1, pp. 3–11, 2018, DOI: 10.1049/it-est.2017.0022.

[3] T. Bertelshofer, R. Hoff, A. Marz, and M. M. Bakran, "Comparing 650V and 900V SiC MOSFETs for the application in an automotive inverter," 2016 18th Eur. Conf. Power Electron. Appl. EPE 2016 ECCE Eur., 2016, DOI: 10.1109/EPE.2016.7695540.

[4] K. Li, A. Videt, N. Idir, P. Evans, and M. Johnson, "Experimental investigation of gan transistor current collapse on power converter efficiency for electric vehicles," 2019 IEEE Veh. Power Propuls. Conf. VPPC 2019 - Proc., pp. 19– 24, 2019, DOI: 10.1109/VPPC46532.2019.8952479.

-

Teléfono

+852 62639182 -

Whatsapp